Motek/Bondexpo 2024: Object recognition with trevista Line Scan

Trevista-dome-pouch-cell-inspection-with-inset. Image: AIT Goehner

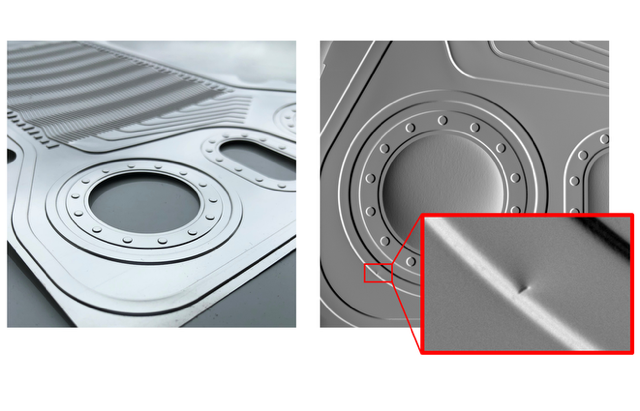

At Motek 2024, AIT Goehner will be presenting trevista Line Scan, the perfect solution for demanding surface inspections. The inspection system uses line scan technology in combination with Cognex’s patented shape-from-shading process to generate optimal image material at high speed. In terms of resource conservation, trevista line scan technology makes a significant contribution to more sustainable production by minimising pseudo rejects and efficient use of raw materials.

2D cameras generate image information in 3D quality and offer the possibility of evaluating topographical information – especially for surfaces that are very shiny, have different reflective properties or black materials. The evaluation of the image data is rule-based and/or based on deep learning algorithms, which offer a fast 100 per cent inspection with extremely high process reliability.

Trevista Line Scan offers significant advantages, especially in predictive maintenance. By continuously capturing image data and transferring it to higher-level systems, conclusions can be drawn about upstream production processes, which increases machine availability and reduces production downtime.The inspection systems are flexible in terms of image field size and resolution; they can be subsequently integrated into existing production lines or as an EoL inspection. The objective assessment of even the finest defects down to the micrometre range minimises pseudo rejects and increases productivity. The system supports the networking of processes by storing image and measurement data for consistent compliance with production standards at different locations.

Target sectors for the AIT test system are automotive manufacturers, suppliers and producers of components for new drive technologies, the medical and pharmaceutical industries and manufacturers of safety-relevant components. The turnkey AIT solution offers an uncomplicated entry into automation, as the user-friendly user interfaces can be customised to meet individual customer requirements. AIT Goehner offers a simple solution to complex surface inspection challenges, which is particularly beneficial for companies looking to optimise productivity without extensive machine vision expertise.

In view of the constantly increasing demands on surface quality and safety, especially for future technologies such as hydrogen or battery storage systems, trevista Line Scan offers an economical and reliable solution. The automated inspection processes eliminate the need for manual visual inspection, which counteracts the shortage of skilled labour.

AIT inspection systems support manufacturers in successfully mastering complex challenges in surface inspection today and in the future.

Bipolar half plate Image: AIT_Goehner